Who we are ...

About Our Industrial Company

Gostaresh Sanat Ghaleb, established in 1984 with the primary goal of producing polymer parts, has since become a leader in the polymer industry through its technical knowledge, management experience, and targeted investments. The company, relying on the efforts and expertise of its technical staff, now produces high-quality and diverse products and collaborates with major automotive and home appliance manufacturers in Iran and internationally.

Additionally, to meet customer needs in polymer and plastic products, Gostaresh Sanat Ghaleb has established a modern mold-making unit equipped with advanced machinery and tools. This unit can produce complex and precise polymer molds for various uses.

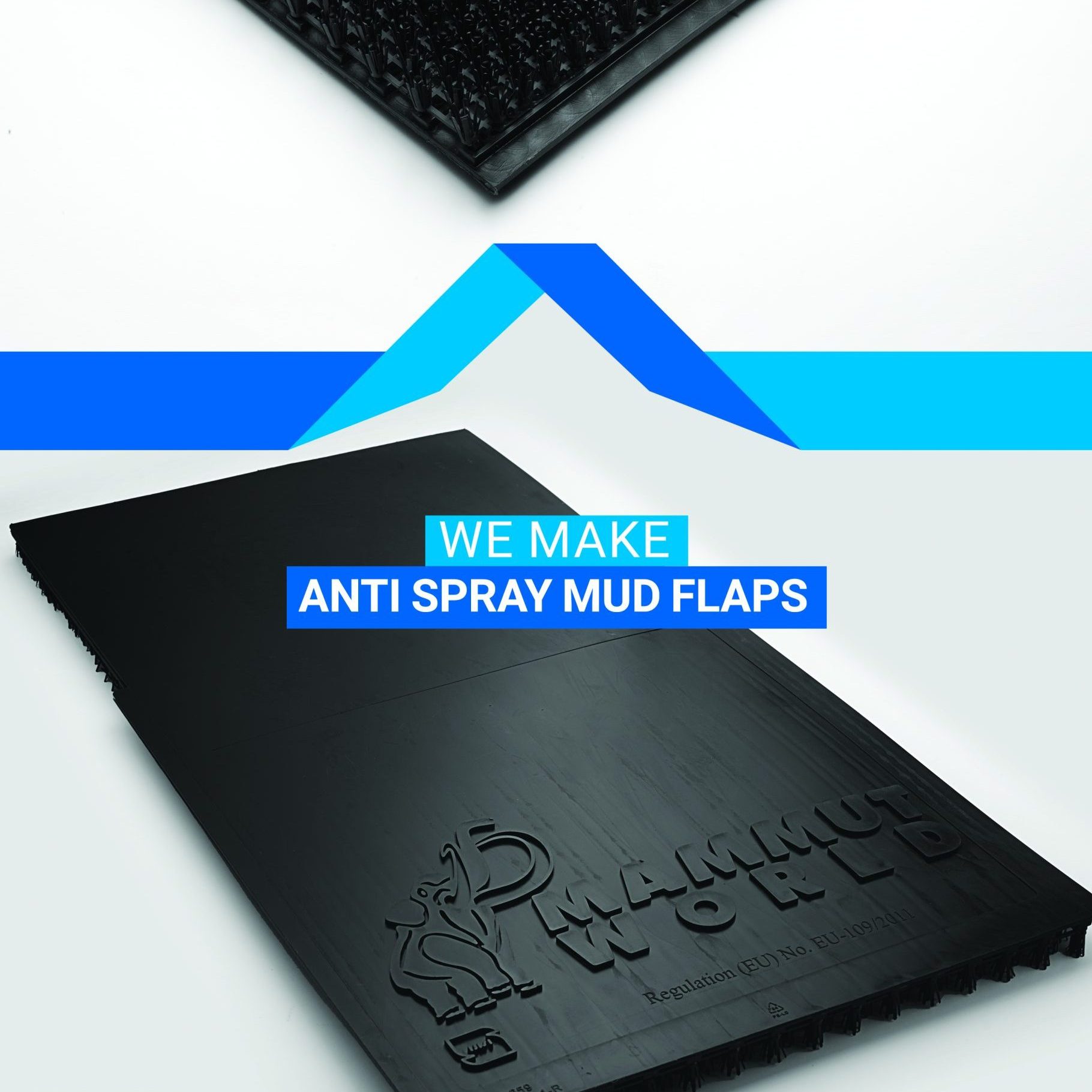

One of Gostaresh Sanat Ghaleb's competitive advantages is its ability to use modern technologies and produce innovative products. For example, it is the sole producer in Iran with a standard certification for manufacturing splash guards, demonstrating its technical and specialized capabilities.

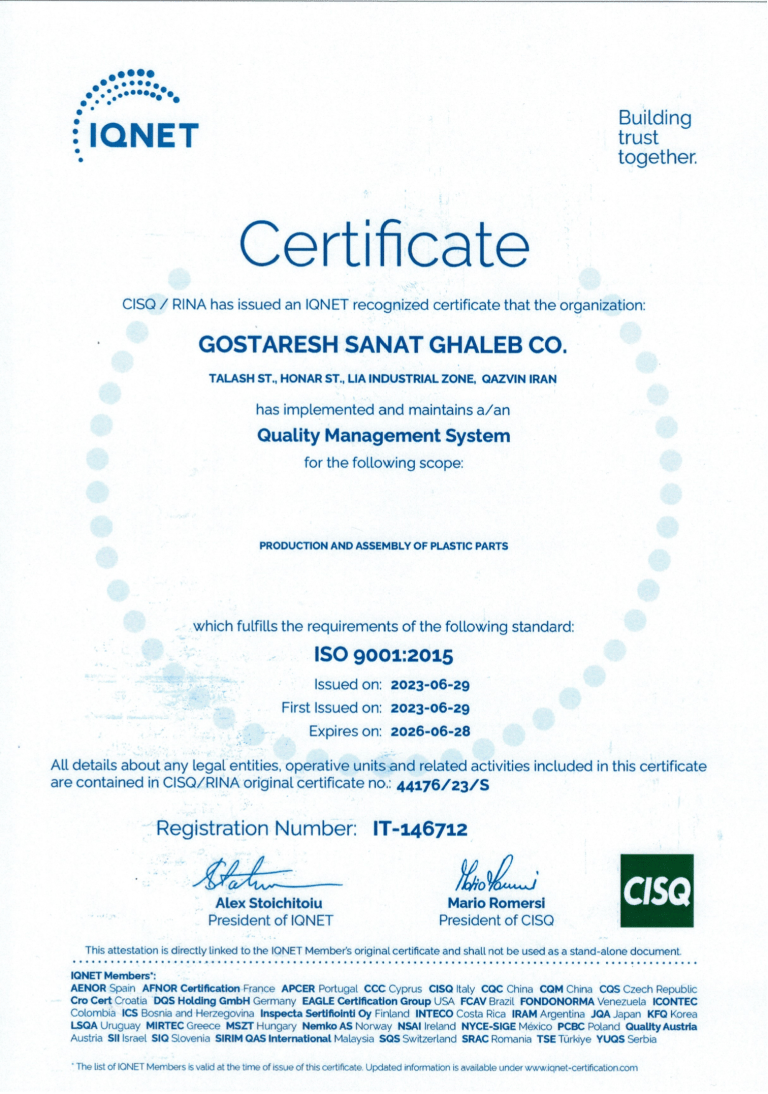

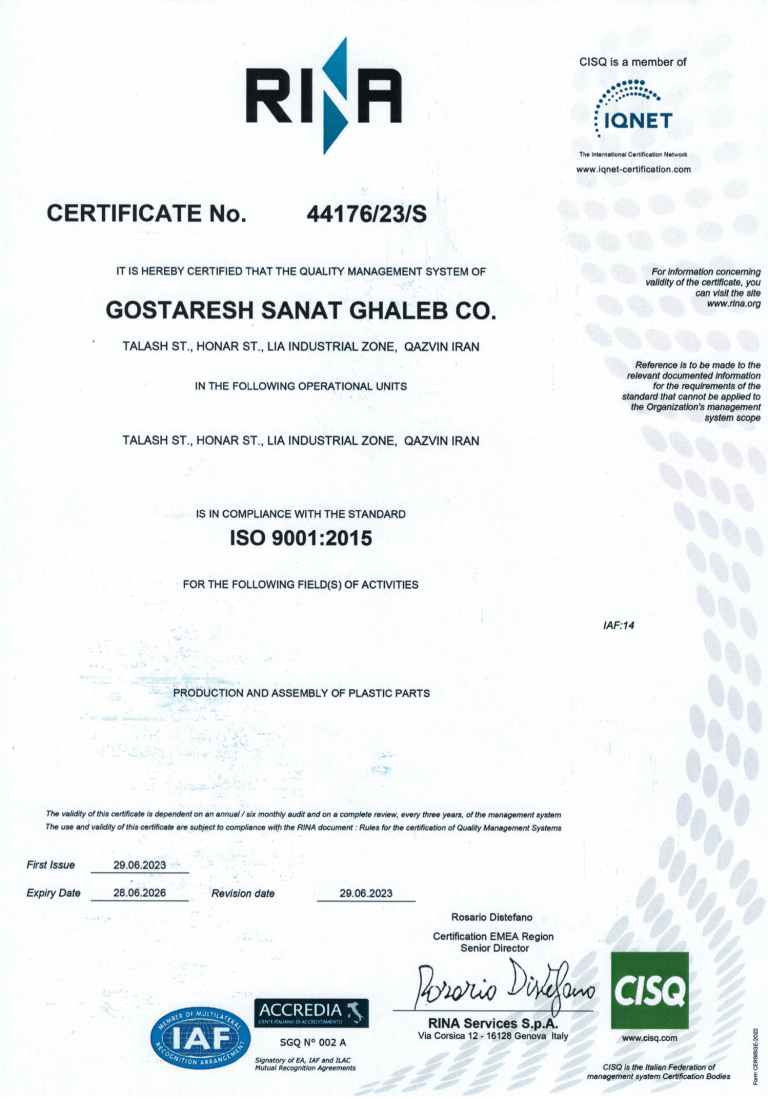

Moreover, the company's products are produced by internationally recognized standards such as ISO/9001:2015, ISO/TS 16949:2016, eMark, and the standards of prominent companies like Iran Khodro, Sapco, Sanden, and well-known home appliance brands. This not only ensures the superior quality of the products but also increases customers' trust in the company's products.

The core philosophy of Gostaresh Sanat Ghaleb is based on a combination of knowledge, expertise, and experience. The company's management believes that sustainable development is achieved through skilled and capable human resources.

Accordingly, the company has made extensive efforts in customer orientation, improving service quality, and employee satisfaction, and serving the interests of its product and service users.

The company's development policies are designed to create the highest value for customers and achieve their maximum satisfaction. These policies include increasing productivity, enhancing technical knowledge, and reducing costs, all aimed at improving the quality and value of the company's products and services.

- Consultation and DesignQuality and Standard

- Manufacturing of PartsQuality and Standard

- Global StandardQuality Assurance of Services

- Modern MachineryFlexibility in Manufacturing

Our Services ...

Our Mission, What Can We Do?

Our experts have utilized their experience and knowledge to ensure that our partners receive the best services and products.

Expert Engineers

We benefit from a combination of knowledge and experience in expanding the mold industry

Industrial Ideas

Not only do we assist you with consulting and design, but we also have the capability to turn an idea into a product with industrial solutions

Projects Support

At every stage of your project, you will have the support of our technical team

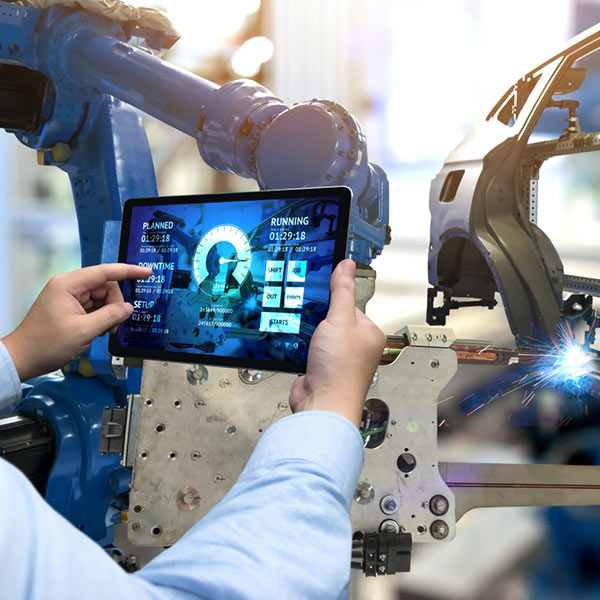

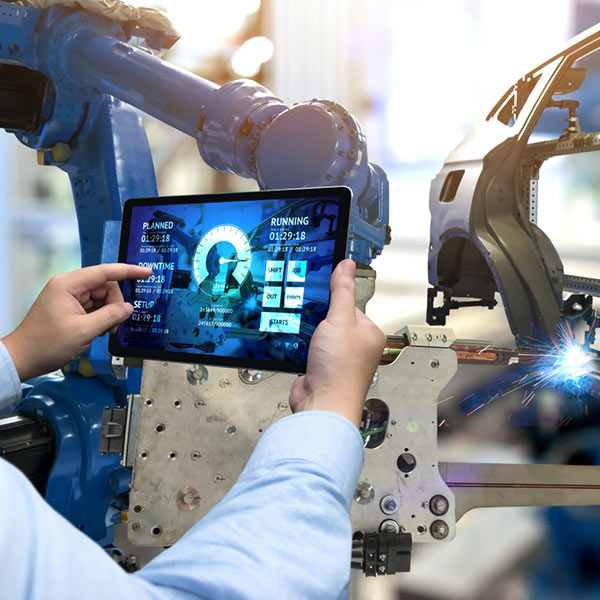

Modern Equipment

With the use of up-to-date, efficient, and modern equipment, the path to providing the best services to customers is clear

The production of polymer parts is a key aspect of modern industry. Polymers, with their unique properties such as flexibility, durability, and lightness, are used in a wide range of applications. The manufacturing processes for these parts include methods like injection molding, extrusion, and laminating. The production of small parts, like medical devices and automotive components, requires high precision, while the production of larger parts, such as car fenders and building equipment, depends on production capacity and material strength. This industry plays an important role in the development of innovative and sustainable products. We can produce any type of polymer parts up to six kilograms.

Designing and constructing plastic injection molds is a complex and specialized process that involves several important stages. Initially, consultation with experts in this field is conducted to accurately identify the needs and requirements of the project. Then, designers use advanced software to design the mold, which must be done with high accuracy and by technical standards. Finally, the mold construction phase begins, which includes cutting, drilling, and other machining processes to create the mold precisely as per the initial design. This process plays a key role in producing high-quality plastic products.

Consultation in the field of polymer parts and plastic injection molds involves a comprehensive review of polymer materials, mold design and construction methods, and optimization of the injection process. This area requires precise technical knowledge about the properties of polymers, their behavior at different temperatures, and environmental impacts on them. Consultation may include selecting suitable materials for a specific application, designing molds to reduce internal stresses and improve the quality of the final part, and providing solutions to improve efficiency and reduce production costs. Ultimately, consultation in this area can help produce high-quality, durable polymer parts.

Gostaresh Sanat Ghaleb's Certificates

We're Hiring, Join Our Industry

Feel free to contact us and send your resume

We are expert in industrial

40 Years of Experience

Consultation, Design, and Manufacturing

Moulding

cutting-edge global technology

As we expand in the mold industry, we as a family continue the legacy of innovation and quality, aiming to enhance the satisfaction and trust of our customers.

Kaveh KolyaeiProduction Manager

As we expand in the mold industry, we as a family continue the legacy of innovation and quality, aiming to enhance the satisfaction and trust of our customers.

Kaveh KolyaeiProduction Manager

As we expand in the mold industry, we as a family continue the legacy of innovation and quality, aiming to enhance the satisfaction and trust of our customers.

فارسی

فارسی English

English